A next-gen power solution redefines active suspension by cutting size in half, enhancing ride quality, and enabling real-time response through high-efficiency 800V-to-48V power conversion.

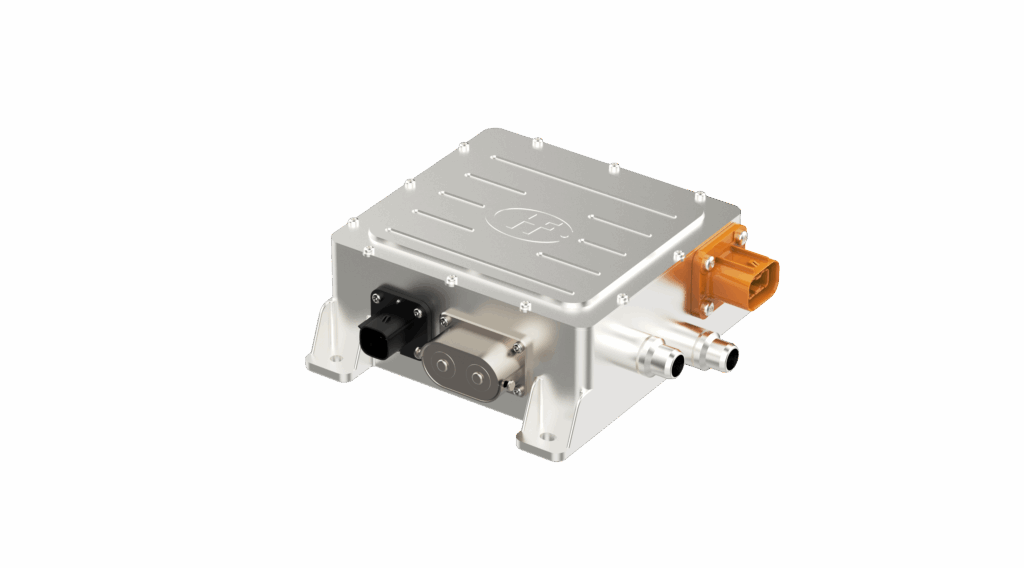

Xiamen Hongfa Electroacoustic Co., Ltd. (Hongfa) has introduced the industry’s smallest and highest-performing active suspension power system, designed to push a once high-end feature into the midrange electric vehicle market. This system successfully overcomes size, weight, and efficiency challenges that have plagued earlier designs for decades.

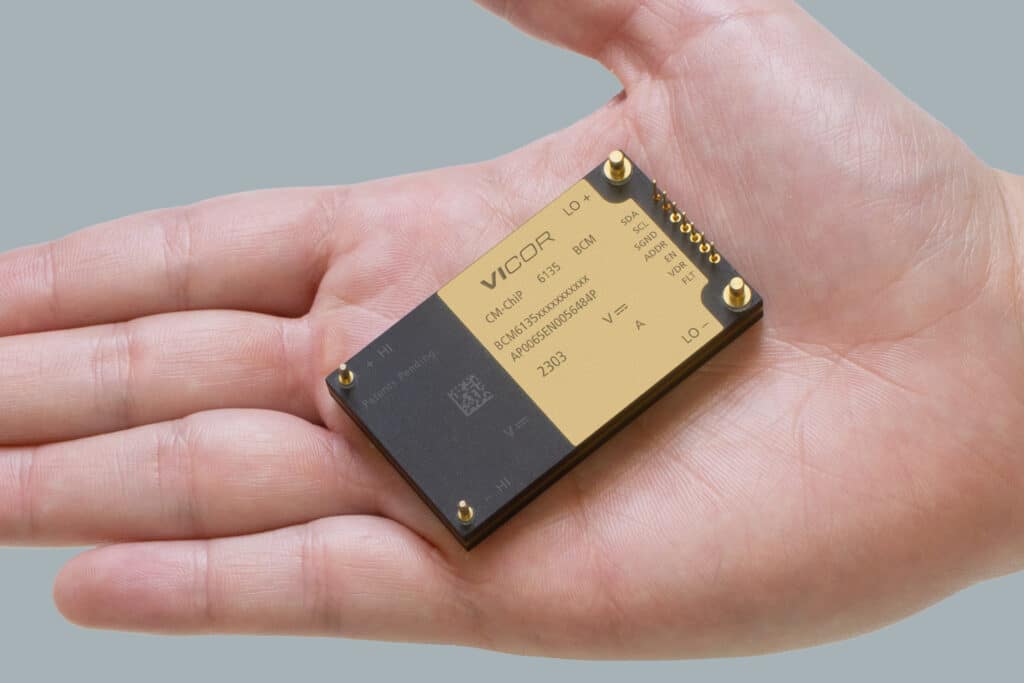

The innovation centers around an ultra-compact 800V-to-48V DC-DC converter module developed in partnership with Vicor, a leader in high-performance power electronics. Unlike legacy systems that relied on bulky motors and underpowered 12V batteries, the Hongfa system leverages modern 48V power delivery networks (PDNs) and high-voltage (800V) batteries, enabling rapid real-time suspension adjustments with superior transient response.

The key specifications are:

- Weighs only 2.6 kg

- Measures 197 x 201 x 71 mm

- Delivers up to 5kW per actuator

- Handles 6kW peak power bidirectionally

- Supports 420V to 920V input

- Achieves 97.3% power conversion efficiency

The solution integrates the company’s BCM6135 bus converters, which provide a fixed-ratio, bidirectional power path with record-fast transient performance—up to 8 million amps per second. These modules simplify the design by eliminating the need for hundreds of discrete components, while their advanced packaging streamlines thermal management and reduces footprint.Enclosed in a compact 1.8-liter volume, the system is nearly 50% smaller than comparable solutions, offering significant space savings without compromising performance. Its liquid-cooled design ensures reliable thermal management, supporting consistent operation even under demanding conditions.

“Fast response is essential in active suspension to avoid adding battery support,” said Peter Li, R&D Director at Hongfa. “Vicor’s modules met our performance targets and helped us accelerate development.”

The result is a transformative leap in automotive suspension, combining reduced weight and size with high energy recovery via regenerative damping. This platform is not only elevating ride comfort and safety but also playing a critical role in the next generation of electrified vehicles.